Base

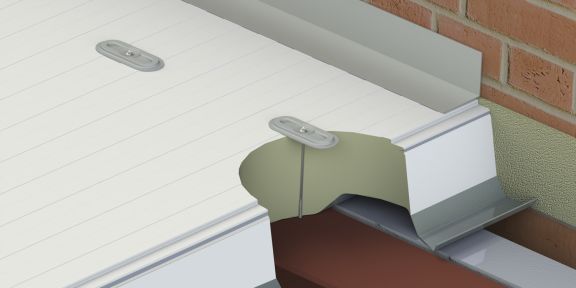

Application

Sandwich panels

Bi-metal A2 304

Steel 5 to 20 mm

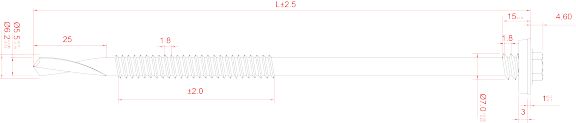

Specifications

- Head style 5/16" (8 mm)

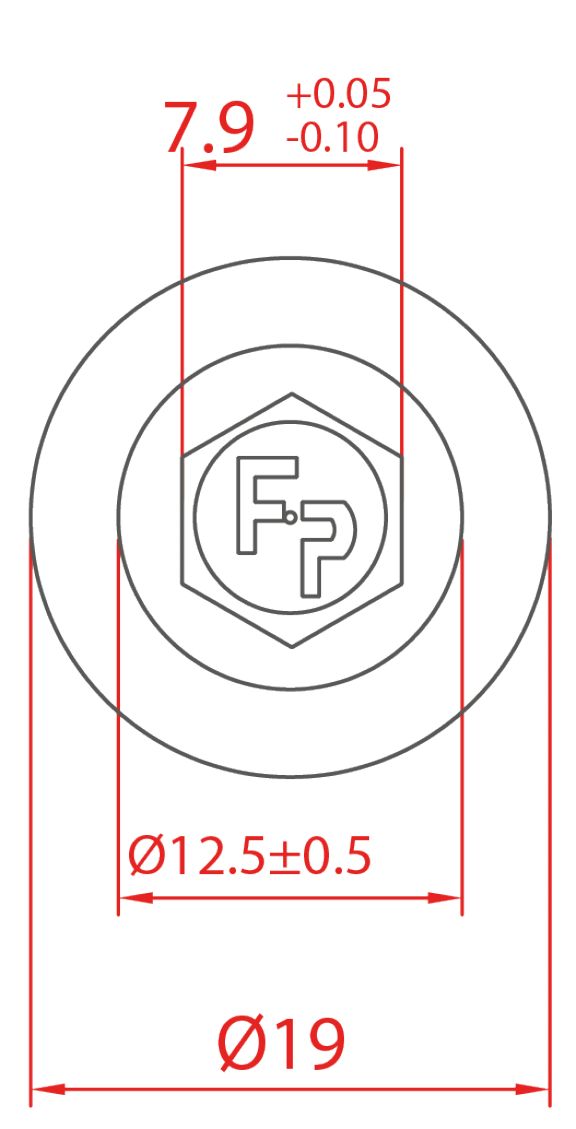

- Washer diameter standard 19 mm

- SS EPDM bond seal

- Support thread

- Thread for substructure steel 5 to 20 mm

- Drilling point S20

Options

- Powder coated in any desired RAL colour

- Washer diameter 16 or 22 mm

Certificates

Section

Applications

Using the table below, the correct length of the fastener can easily be determined.

| Size | Minimal Insulation thickness | Article code | ||||||

|---|---|---|---|---|---|---|---|---|

| 80.0 | 100.0 | 120.0 | 140.0 | 160.0 | 180.0 | 200.0 | ||

| 6,3/7,0 x 170 mm | 90 - 120 mm

|

1001Q76317019 | ||||||

| 6,3/7,0 x 190 mm | 110 - 140 mm

|

1001Q76319019 | ||||||

| 6,3/7,0 x 230 mm | 150 - 180 mm

|

1001Q76323019 | ||||||

| 6,3/7,0 x 250 mm | 170 - 200 mm

|

1001Q76325019 | ||||||

| 6,3/7,0 x 270 mm | 190 - 220 mm

|

1001Q76327019 | ||||||

Order information

| Product | Afmeting | Verpakking | Artikelcode |

|---|---|---|---|

| Paneelbevestiger 6,3-7,0 x 170 – S20 | 170 mm | 100 st/doos | 1001Q76317019 |

| Paneelbevestiger 6,3-7,0 x 190 – S20 | 190 mm | 100 st/doos | 1001Q76319019 |

| Paneelbevestiger 6,3-7,0 x 230 – S20 | 230 mm | 100 st/doos | 1001Q76323019 |

| Paneelbevestiger 6,3-7,0 x 250 – S20 | 250 mm | 100 st/doos | 1001Q76325019 |

| Paneelbevestiger 6,3-7,0 x 270 – S20 | 270 mm | 100 st/doos | 1001Q76327019 |

Mechanical properties

16 mm

19 mm

22 mm

| Materials | ||

|---|---|---|

| Screw | RVS 1.4301 (A2) - conform EN3506 |

|

| Bond washer | RVS 1.4301 (A2) - conform EN3506 | |

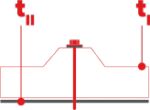

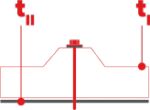

| Material A (tl) | S280GD, S320GD and S350GD conform EN 10346 | |

| Material B (tll) | S235 conform EN 10025-2, S280GD, S320GD and S350GD conform EN 10346 | |

| Drilling capacity | Steel ≤ 20 mm | |

Washer diameter

16 mm

| tN1 [mm] | tII [mm] | |||||||||||||||||

| 0.75 | 0.88 | 1 | 1.13 | 1.25 | 1.5 | 2 | 3 | 6 | 10 | |||||||||

.png?width=100&height=100&mode=fit&format=jpeg&signature=aa41c7e1477cf02000b0b5a95a5df13578693b65

)

|

VR,k [kN] | 0.4 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | ||||||

| 0.5 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | ||||||||

| 0.55 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | ||||||||

| 0.63 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | ||||||||

| 0.75 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 0.88 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1.13 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1.25 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

|

NR,k [kN] | 0.4 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.59 | 1.59 | 1.59 | 1.59 | 1.59 | ||||||

| 0.5 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.68 | 1.68 | 1.68 | 1.68 | 1.68 | ||||||||

| 0.55 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 1.81 | 1.81 | 1.81 | 1.81 | ||||||||

| 0.63 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.02 | 2.02 | 2.02 | 2.02 | ||||||||

| 0.75 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.34 | 2.34 | 2.34 | 2.34 | ||||||||

| 0.88 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.61 | 2.61 | 2.61 | ||||||||

| 1 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.61 | 2.61 | 2.61 | ||||||||

| 1.13 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.61 | 2.61 | 2.61 | ||||||||

| 1.25 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.61 | 2.61 | 2.61 | ||||||||

|

u [mm] | 40 | 10 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 3 | 3 | ||||||

| 50 | 12.5 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 3.5 | 3.5 | ||||||||

| 60 | 15 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 4.5 | 4.5 | ||||||||

| 80 | 20 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 6 | 6 | ||||||||

| 100 | 25 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 7.5 | 7.5 | ||||||||

| 120 | 30 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 9 | 9 | ||||||||

| ≥160 | 40 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 12 | 12 | ||||||||

- Above mentioned values are characteristic values

- To determine the design value we advise to apply a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | RVS 1.4301 (A2) - conform EN3506 |

|

| Bond washer | RVS 1.4301 (A2) - conform EN3506 | |

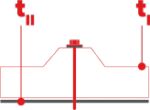

| Material A (tl) | S280GD, S320GD and S350GD conform EN 10346 | |

| Material B (tll) | S235 conform EN 10025-2, S280GD, S320GD and S350GD conform EN 10346 | |

| Drilling capacity | Steel ≤ 20 mm | |

Washer diameter

19 mm

| tN1 [mm] | tII [mm] | |||||||||||||||||

| 0.75 | 0.88 | 1 | 1.13 | 1.25 | 1.5 | 2 | 3 | 6 | 10 | |||||||||

.png?width=100&height=100&mode=fit&format=jpeg&signature=aa41c7e1477cf02000b0b5a95a5df13578693b65

)

|

VR,k [kN] | 0.4 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | ||||||

| 0.5 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | ||||||||

| 0.55 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | ||||||||

| 0.63 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | ||||||||

| 0.75 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 0.88 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1.13 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1.25 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

|

NR,k [kN] | 0.4 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 1.88 | 1.88 | 1.88 | 1.88 | ||||||

| 0.5 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.26 | 2.26 | 2.26 | 2.26 | ||||||||

| 0.55 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.48 | 2.48 | 2.48 | ||||||||

| 0.63 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.83 | 2.83 | 2.83 | ||||||||

| 0.75 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.35 | 3.35 | 3.35 | ||||||||

| 0.88 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.89 | 3.89 | ||||||||

| 1 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.89 | 3.89 | ||||||||

| 1.13 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.89 | 3.89 | ||||||||

| 1.25 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.89 | 3.89 | ||||||||

|

u [mm] | 40 | 10 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 3 | 3 | ||||||

| 50 | 12.5 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 3.5 | 3.5 | ||||||||

| 60 | 15 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 4.5 | 4.5 | ||||||||

| 80 | 20 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 6 | 6 | ||||||||

| 100 | 25 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 7.5 | 7.5 | ||||||||

| 120 | 30 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 9 | 9 | ||||||||

| ≥160 | 40 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 12 | 12 | ||||||||

- Above mentioned values are characteristic values

- To determine the design value we advise to apply a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | RVS 1.4301 (A2) - conform EN3506 |

|

| Bond washer | RVS 1.4301 (A2) - conform EN3506 | |

| Material A (tl) | S280GD, S320GD and S350GD conform EN 10346 | |

| Material B (tll) | S235 conform EN 10025-2, S280GD, S320GD and S350GD conform EN 10346 | |

| Drilling capacity | Steel ≤ 20 mm | |

Washer diameter

22 mm

| tN1 [mm] | tII [mm] | |||||||||||||||||

| 0.75 | 0.88 | 1 | 1.13 | 1.25 | 1.5 | 2 | 3 | 6 | 10 | |||||||||

.png?width=100&height=100&mode=fit&format=jpeg&signature=aa41c7e1477cf02000b0b5a95a5df13578693b65

)

|

VR,k [kN] | 0.4 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | ||||||

| 0.5 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | 1.48 | ||||||||

| 0.55 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | 1.74 | ||||||||

| 0.63 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 | ||||||||

| 0.75 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 0.88 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1.13 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

| 1.25 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | ||||||||

|

NR,k [kN] | 0.4 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 1.96 | 1.96 | 1.96 | 1.96 | ||||||

| 0.5 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.61 | 2.61 | 2.61 | ||||||||

| 0.55 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.75 | 2.75 | 2.75 | ||||||||

| 0.63 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 2.98 | 2.98 | 2.98 | ||||||||

| 0.75 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.33 | 3.33 | 3.33 | ||||||||

| 0.88 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.86 | 3.86 | ||||||||

| 1 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.86 | 3.86 | ||||||||

| 1.13 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.86 | 3.86 | ||||||||

| 1.25 | 0.59 | 0.79 | 0.97 | 1.17 | 1.35 | 1.73 | 2.48 | 3.78 | 3.86 | 3.86 | ||||||||

|

u [mm] | 40 | 10 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 3 | 3 | ||||||

| 50 | 12.5 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 3.5 | 3.5 | ||||||||

| 60 | 15 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 4.5 | 4.5 | ||||||||

| 80 | 20 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 6 | 6 | ||||||||

| 100 | 25 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 7.5 | 7.5 | ||||||||

| 120 | 30 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 9 | 9 | ||||||||

| ≥160 | 40 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 12 | 12 | ||||||||

- Above mentioned values are characteristic values

- To determine the design value we advise to apply a material factor of γm = 1,33.